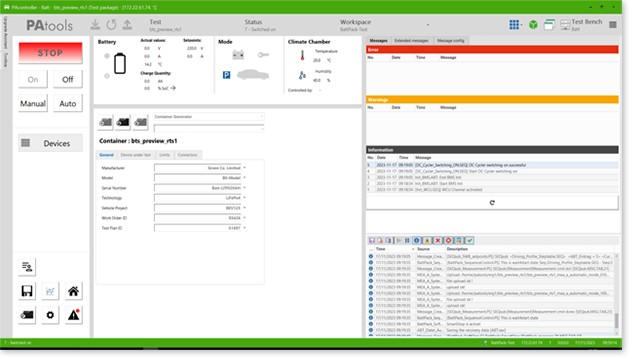

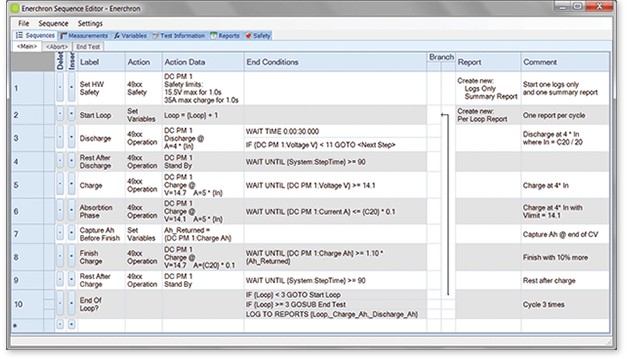

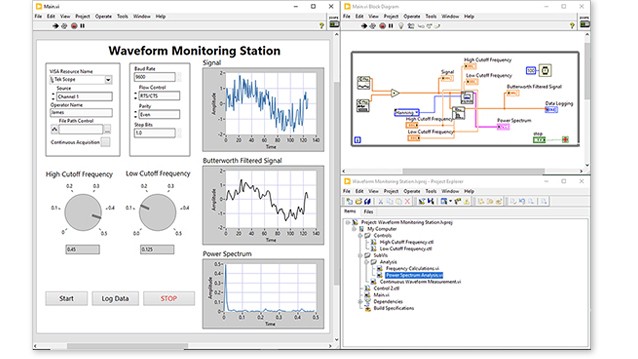

Enerchron ist ein leistungsstarkes und dennoch benutzerfreundliches Testprogramm, das für Batterietests entwickelt wurde, um die Testautomatisierung zu vereinfachen und zu beschleunigen. Mit einer umfassenden Batterietestumgebung, die die Integration in Hardware- und Softwaretools beinhaltet, ist Enerchron Ihr kürzester Weg zur Marktreife.